Las Vegas, NV - An exclusive active monitoring system to allow mining companies to remotely monitor wear liners in real-time was announced by manufacturers AbrecoⓇ at MINExpo 2021. Abreco IoT is the latest innovation in mining technology that provides the status of all connected liners within a system thus reducing requirements for physical inspections.

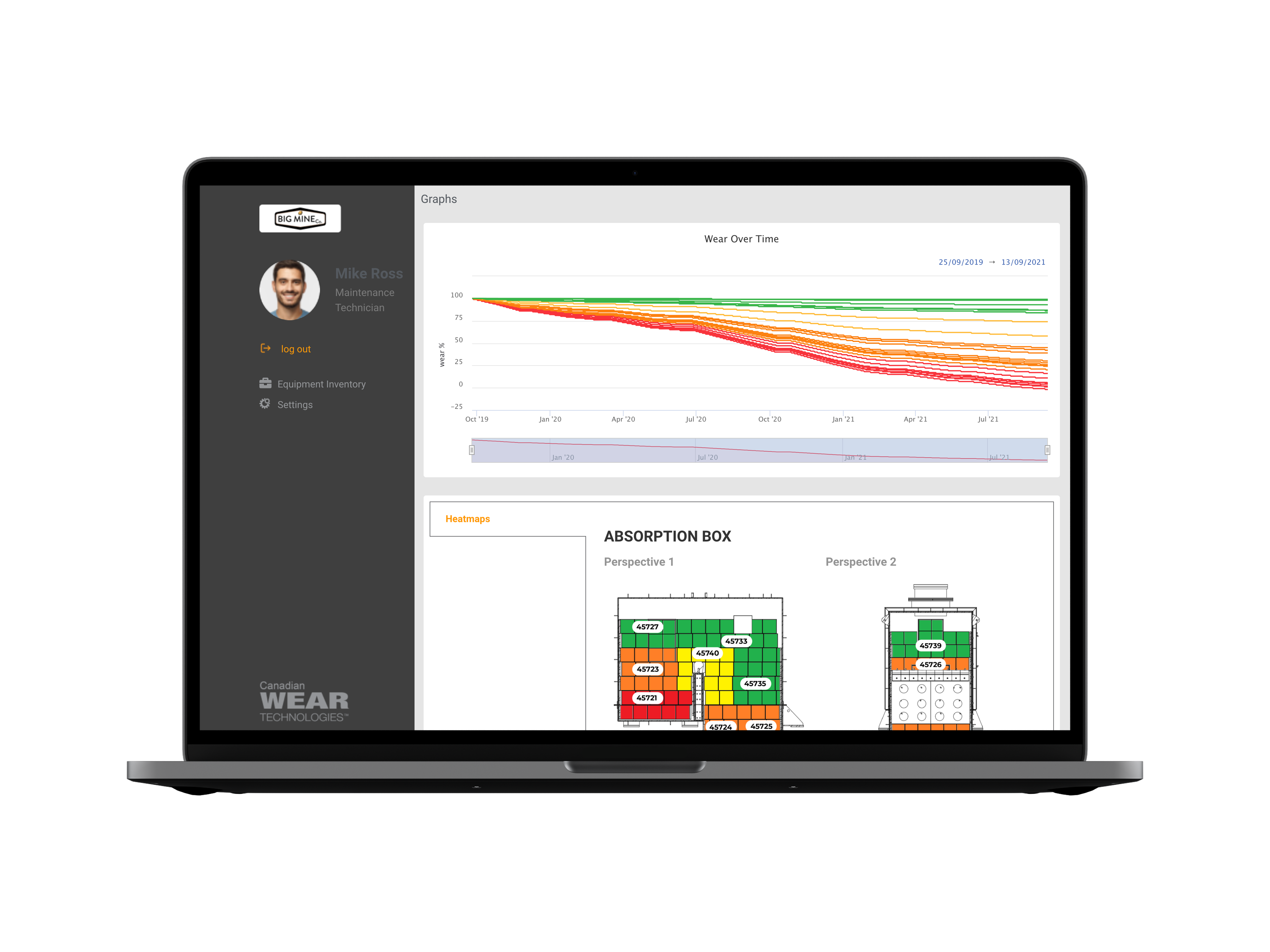

Wear liners can be monitored through the Abreco IoT exclusive and secure dashboard so data such as active heat maps can be viewed from anywhere. Abreco IoT provides the status of all wear liners connected to the system with detailed information that enables forecasting planned outages with a high degree of precision.

The improved reliability that Abreco IoT provides for wear liner monitoring can greatly reduce downtime which translates to substantial cost savings for mining companies. It is estimated that the cost of a shutdown to a mine is more than $1M in lost production.

Abreco IoT virtually eliminates the downtime related to monitoring wear liners, makes wear liner inspections and maintenance safer and substantially reduces wear liner inspection costs and risks.

An industry leader, Abreco manufactures mining wear products for several industries including mining, steel, cement, aggregate, power generation and OEMs. The company has its own foundry to produce custom castings and an engineering team to provide comprehensive wear analyses and recommendations. Visit abrecoiot.com to learn more.

Five Different Types of Mining Plant Maintenance

Maintenance in the mining industry is a required necessity due to the size, volume and complexities involved in each operation. The cost of maintenance can be as high as 50% of the planned production...