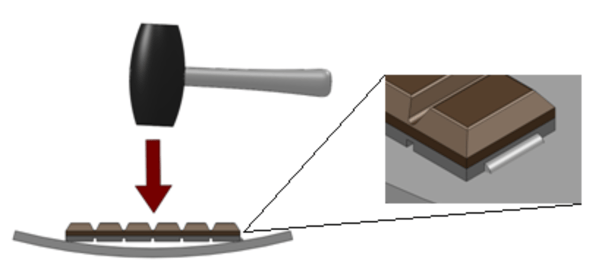

The Abreco Chok Bar is ideal for bucket and shovel protection. They are compact and light, making them easy to handle for installation and quick fixes. To install on curved wear surfaces Abreco Chok Bar should be orderd notched (add "N" to suffix code).

It is normal for the Chokbar to crack during forming.

- Clean the mating surface to which the Chokbar will be welded.

- Tack weld one segment at the end of the Chokbar on all three sides (per Abreco welding procedure)

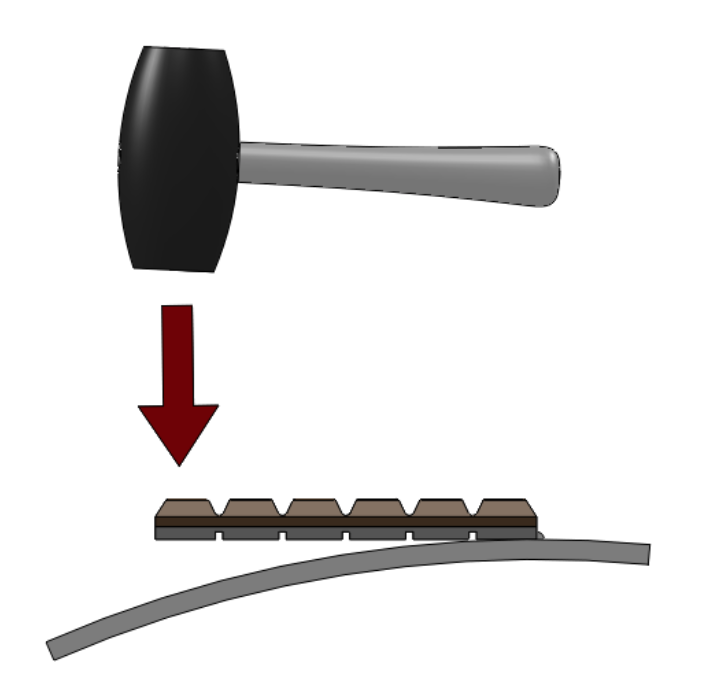

For Outside Curve:

- Hammer down free end of Chokbar with soft hammer to mate with radius of desired surface. (Figure 1)

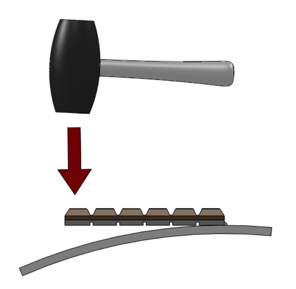

For Inside Curve:

- Strike bar with soft hammer, in center of bar, to bend Chok Bar to mate with radius of desired surface. (Figure 2)

- Stitch weld formed bar to curved surface as per Abreco welding procedure

Figure 1: Outside Curve Figure 2: Inside Curve

Pour les procédures de formation du Chok Bar en français, cliquez ici.

.png)